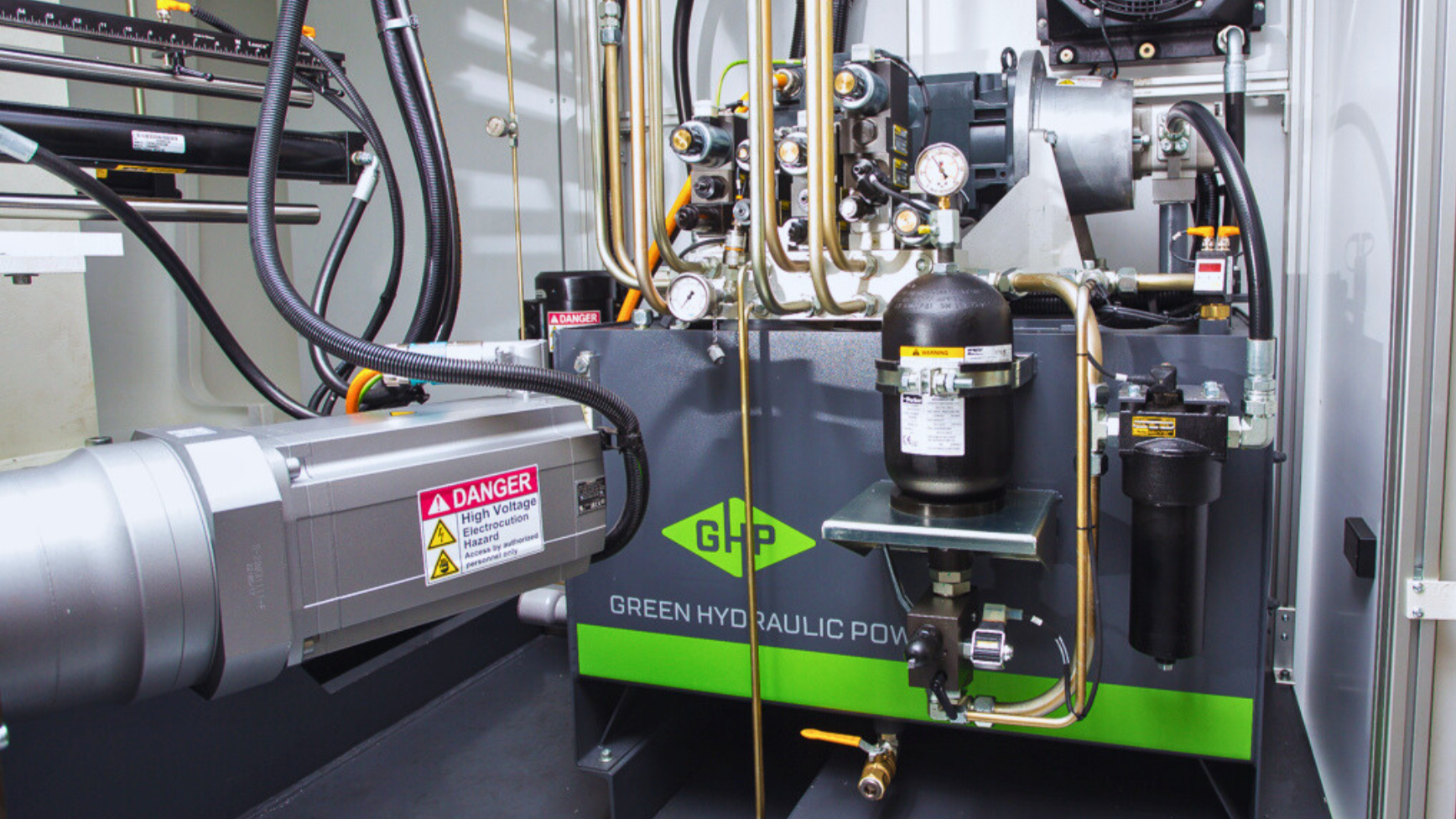

Engineered for Real-World Manufacturing Challenges

From press lines that pause between strokes to machines running under partial load, GHP’s variable-speed hydraulic systems adapt to your operation—delivering cleaner energy, quieter floors, and actionable data without costly re-engineering.

Solutions for Demanding Hydraulic Applications

-

Machine Tools & Test Stands

Pain Points:

· Mixed duty cycles and partial-load inefficiencies

· Pressure stability impacts part quality

· High peak demand charges

Solution Benefits:

· Smooth ramps, stable pressure, better measurement fidelity

· Lower noise during partial load and idle

· Reduced peak demand charges with smart drive profiles

-

Packaging & Assembly

Pain Points:

· Frequent starts/stops and operator proximity

· Noise and heat affect safety and comfort

· Inconsistent flow at low demand

Solution Benefits:

· Precise flow control at low demand

· Quieter, cooler cells for safer environments

· Enhanced data visibility for continuous improvement

-

Plastics & Injection Molding

Pain Points:

· Standby energy near nameplate power

· Heat spikes and maintenance alarms

· Cycle consistency challenges

Solution Benefits:

· Standby kWh cut with variable speed

· Cooler operation and fewer alarms

· Stable pressure profiles for consistent cycles

-

Metal Forming & Presses

Pain Points:

· High energy draw at idle and hold

· Heat accumulation impacting oil life and seals

· Operator fatigue from noise

Solution Benefits:

· Demand-driven RPM reduces idle/hold waste

· Lower reservoir temps extend component life

· Noticeably quieter floors—especially during staging

CONFIGURATION OPTIONS

Standard units or Custom Engineered Systems

Standard VFD-driven HPU’s for common duty cycles

Custom pump/motor sizing, sensor suites, and controls

Integration support: electrical, mechanical, PLC/HMI

Not Sure Where to Start?

Starting with hydraulic power doesn’t have to be complicated. From the first conversation to full system integration, we work closely with your local technicians and trusted professionals to ensure everything runs smoothly. Our collaborative approach means you get expert guidance without disrupting your existing workflow—so you can enjoy energy savings, reliable performance, and peace of mind from day one.