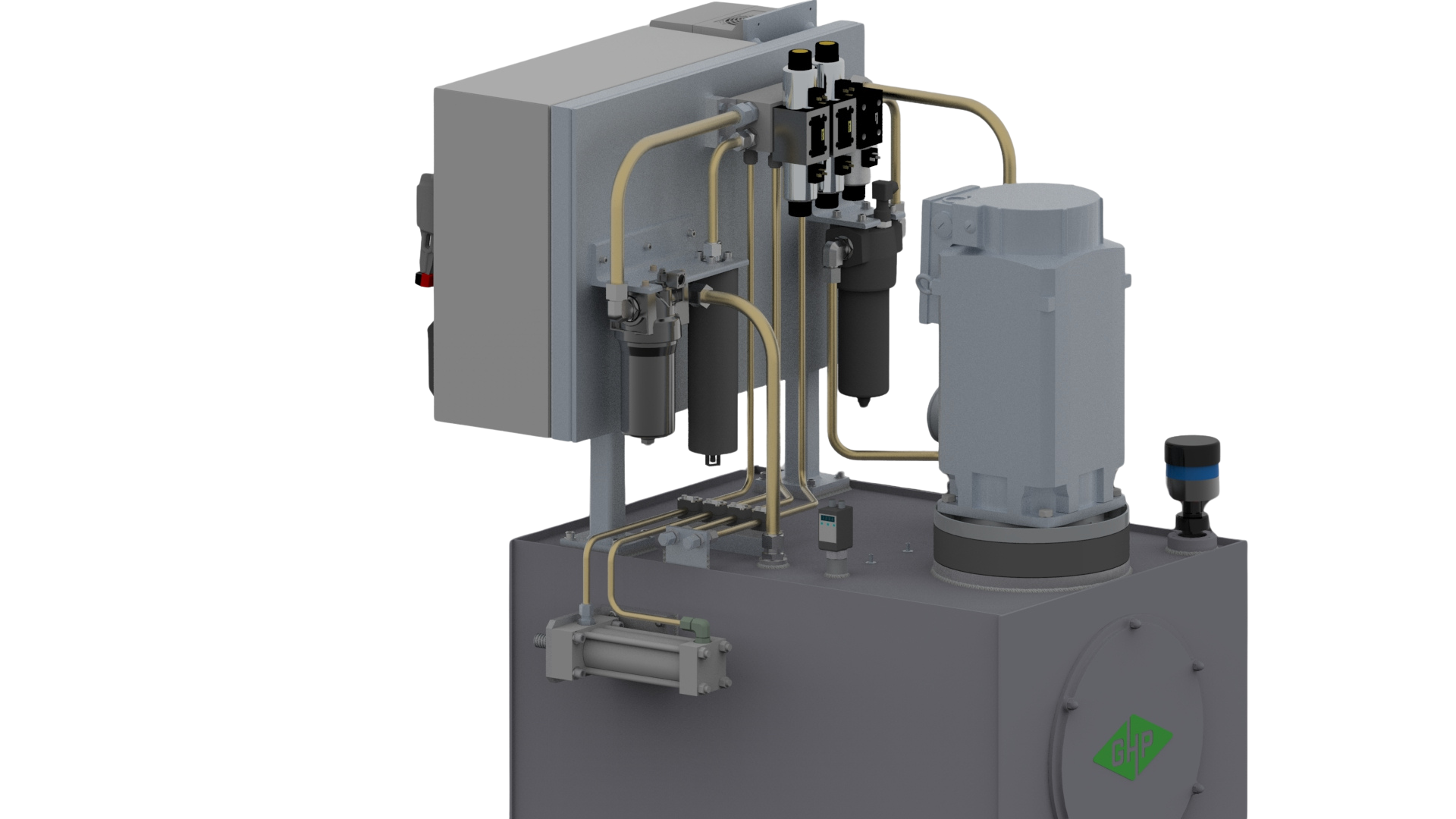

How Variable Speed Makes Hydraulics Better

Fixed-speed motors spin at constant RPM regardless of demand, consuming excess energy during idle and partial load, producing unnecessary noise and heat. GHP’s variable-speed approach solves this by continuously matching motor speed—and therefore pump flow and torque—to real-time system needs.

The Hidden Cost of Fixed-Speed HPUs

-

Constant RPM means constant energy draw—even when flow demand is low

-

Excess energy turns into heat, raising fluid temperature and stressing components

-

High idle noise impacts operator comfort and safety

Motor + Drive + Sensors + Controls

— Working Together

THE GHP APPROACH

The drive listens.

The motor responds.

The pump delivers only what the system needs.

-

Variable Frequency Drive:

Adjusts motor RPM in real time based on demand

-

Smart Sensors:

Pressure, temperature, and flow inputs feed control logic

-

Control Algorithms:

Optimize speed/torque for stability and responsiveness

-

Hydraulic Integration:

Delivers exact flow and pressure, reducing overconsumption and heat

Immediate Differences on the Plant Floor

-

Energy:

Demand-matched kWh and fewer peak demand charges

-

Noise:

Lower RPM at idle/partial load significantly reduces dB

-

Heat:

Cooler reservoirs, longer oil life, fewer leaks

-

Control:

Smoother ramps and stable pressure profiles improve quality

Easy to Integrate with Your Controls

-

PLC/HMI-friendly

-

Electrical and mechanical fit-up support

-

Data visibility for maintenance and sustainability reporting

Frequently Asked Questions

-

No. Controls continuously maintain target pressure and flow, with fast response to transients.

-

In most cases, yes. We assess motor/pump sizing, duty cycle, and control integration to recommend the right path.

-

Depends on hours, utility rates, and duty cycles. Many projects reach payback in [X–Y months].

-

You can reach us anytime via our contact page or email. We aim to respond quickly—usually within one business day.

-

We offer flexible pricing based on project type and complexity. After an initial conversation, we’ll provide a transparent quote with no hidden costs.

-

Collaborative, honest, and straightforward. We're here to guide the process, bring ideas to the table, and keep things moving.